Background

In today's oilfields, where cost and efficiency are key, oil companies need a comprehensive data set from every well drilled. Surface measurement while drilling or SMWD makes available the full potential of fluids and drilling cuttings. The data collected is valuable in itself. The purpose of surface measurement during drillingis quantitative data on the characteristics of cuttings and drilling fluid received from the bottom of the well and displaying that information in a way that is meaningful to the rig operators. Continuous analyzes simultaneously with drilling on fluid and cuttings of drilling are all-round monitoring of drilling operations as well as performing technical and specialized calculations and wellhead analyses which finally provides very valuable information about the subsurface condition of the earth's layers as well as the condition of the drilling operation on the drilling rig. All these real-time data obtained by artificial intelligence software are used to increase drilling efficiency, improve geosteering and optimize the well completion process. SMWD is a method to obtain geochemical information that cannot be obtained by means bottom of the well tools and cores. The most important methods of surface measurement during drilling or SMWD include:

GeoHC

The presence of hydrocarbon gas (C 1 -C 8 ) while drilling can indicate the presence of a potential reservoir of oil or gas and reflect the reservoir fluid type, location, extent of the hydrocarbon-bearing formation, and petrophysical characteristics of the drilled rocks.

Benefits

-Real-time Lithological Changes

-Hydrocarbons Content

-Water Contacts

-Vertical Changes in fluid over a pay interval

-Fluid Characterization (Phase/Wh/Bh/GLR/LHR/FS/PI/FMPP and etc.)

GeoROX

Inorganic Real-Time Field Geochemistry Analysis on Cuttings

GeoROX provides detailed chemical and mineralogy rock characterization on drill cuttings and core chips. A combination of X-Ray Fluorescence (XRF) analysis and X-Ray

Diffractometry (XRD) measurements are obtained in near real-time at the well site. All key chemical, mineralogy, and geomechanical information are delivered within 1-2

hours of drilling through a formation.

Benefits

-Mineral Brittleness evaluation for planning hydraulic stimulation

-Chemostratigraphic models used for picking casing and core points

-Replace downhole elemental spectroscopy and spectral gamma ray

-Obtaining geochemical data in near real-time, compared to delayed lab results

-Understanding diagenetic changes and depositional history

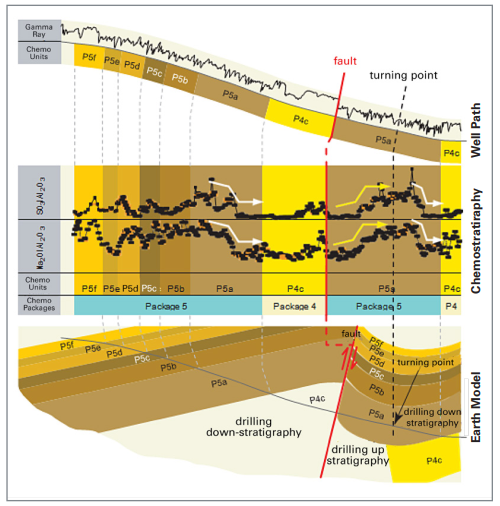

-Aiding horizontal well placement and trajectory via chemosteering

-Realtime data to improve completion strategies

GeoSource

Real-Time Total Organic Carbon (TOC) and Pyrolysis in the field

GeoSource service provides wellsite geochemical analysis of reservoir and source rocks. GEOLOG specialists are then able to characterize the organic matter present in the

rock for evaluation of the source rock potential, maturity and origin. GeoSource is unique because it provides TOC and Pyrolysis information in the field using GEOLOG

designed and built, fit for purpose equipment.

Benefits

-Direct measurement of TOC – unlike inferred wireline calculations

-Rapid identification of sweet spots for enhanced completion design

-Identify best source rock for horizontal well placement

-Analytical process and data directly comparable with conventional lab results

-Early analysis of Kerogen typing vs lab results

GeoFL

The total scanning fluorescence (TSF) technique uses a more sophisticated ultraviolet (UV) spectroscopic instrument and generates a 3D fluorescence spectrum or

"fingerprint." This spectrum results from the total fluorescence contribution of the fluorescing species present in the oil.

Benefits

-Oil fingerprinting in vertical pay zones

-Direct measurement of PAH FL properties to define Hydrocarbon Type

-Inferred API

-Identify Migration Distance using R1

-Identify Thermal Maturity using R1

GeoNMR

Nuclear Magnetic Resonance mud logging technology (NMR mud logging) is a new mud logging technology. Mainly applies the CPMG(Carr-Purcell-Meiboom-Gill pulse

sequence to measure transverse relaxation time (T2) of the fluid. NMR mud logging can measure drill cutting, core and sidewall core in the well site, also according to the

experiment results, the sample type and size has little effect to analysis result.

Benefits

-provide porosity,

-permeability,

-oil saturation,

-Movable fluid saturation,

-irreducible water saturation,

-movable water saturation with high precision from rock sample

Applications

- Determining the type of hydrocarbon in the reservoir

- API estimation of reservoir hydrocarbons

- Evaluation of petrophysical properties, zoning and correlation of formations

- Geochemical evaluation of source rock

- Chemical stratigraphic studies and elemental zoning in facies

- Determination of lithology and diagenesis parameters

- Formation gas measurement and evaluation

- Find the connection and identify anomalies related to faults, fractures or lateral facies changes

Benefits

- Use without disruption in drilling operations

- Economical alternative to LWD downhole measurement tools

- Increasing drilling efficiency, completing the optimization process with accurate prediction of pay zone intervals

- Increasing the probability of finding new hydrocarbon zones during drilling

- Reliable laboratory scale data