Background

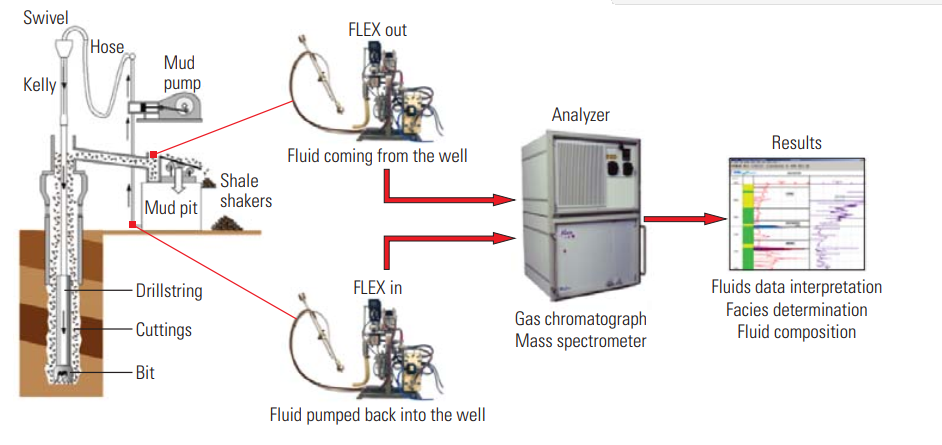

Identifying the type of fluid while drilling in a tight reservoir is essential for all technical disciplines that manage or supervise drilling activities (eg, geologists, petrophysicists, drilling and reservoir engineers) in order to implement and/or modify the proposed well program. One of the most common methods for formation evaluation and fluid identification during drilling is LWD, but this method has uncertainty in tight reservoirs and requires the support of GWD data. The process of obtaining formation fluid data from the drilling fluid during drilling can be divided into two separate and equally important functions. Extraction of gas bubbles from the drilling fluid, and continuous analysis of these gases at the well site. Gas extraction in this case is important both in terms of the volume and temperature of the mud being degassed and in terms of the speed of the extracted gas flow to the analytical tools. One type of extractor, the constant volume and temperature gas trap (HCVD) allows for repeatability of readings and eliminates one of the main detractors in gas data quality, which is changes in mud level and flow. This device is able to separate C1 to C5 gases and extract C6 to C8 compounds from drilling mud in this way, it heats compounds larger than C6 due to their liquid nature in atmospheric conditions at the appropriate temperature to turn them into gas and transfer them to the measurement system along with C1 to C5 gases to continue the process. The gas transmission system to the drilling mud mapping unit, which consists of a gas transportation line approximately 50 meters long, should be designed so that C6+ compounds do not turn into liquid on the way.

For this purpose, proper heating and insulation is considered for the gas transmission line (Heated Gas Line) so that the desired compounds are transferred to the measurement system in suitable conditions through the gas flow control system. In the gas transmission path, a purification and filtration system is also installed to prevent the arrival of moisture and impurities of solid particles and hydrogen sulfide, which cause damage to the measurement system. In this way, the gas flow control and distribution system enables the gas sample to all the gas detectors, so that each of them receives a sufficient amount of the sample. Then the obtained gas sample is continuously fed to the gas analyzers. Gas chromatographs analyze methane gases, the lightest and most abundant hydrocarbons, down to normal octane. The detection tool chosen for this device is a flame ionization detection (FID) system with a chromatography column, which continuously separates and measures the range of hydrocarbons (C1, C2, C3, iC4, nC4, iC5, nC5, nC6, nC7, nC8, benzene, cyclohexane, methylcyclohexane and toluene) enables a better understanding of the formation fluid.

Such derivatives, especially the heavier compounds, may be present in very low concentrations (ppm). The FID detectors used, however, have a sensitivity of 1 ppm. The most important challenge in the hydrocarbon gas measurement device is the rapid and continuous analysis of the gas flow separated from the drilling fluid. In this way, the measurement in the online gas chromatography device should be under 60 seconds for light compounds (C1-C5) and for heavier compounds (C6-C8) under 120 seconds, the resulting result should be compared to its corresponding drilling depth. In order to solve this challenge, special columns are used for the quick separation of impurities and the Back Flush system and quick return to the initial conditions in the gas chromatography machine.

The following geochemical equations and gas ratios can be used in conventional and unconventional reservoirs. The primary ratios used in formation evaluation and reservoir fluid characteristics interpretation are as follows:

- Total hydrocarbon components (THC)

- Fluid mobility/potential porosity ratio FM/PP

- gas/liquid ratio

- HC

- ARO/ALK

- Light Heavy Ratio (LHR)

- WH (Wetness) vs. BH (Balance) vs. CH (Character)

- Fluid Saturation (FS)

Application

- Evaluation and identification of productive intervals during drilling

- The possibility of identifying the surface of oil-water contacts (OWC) during drilling

- The possibility of identifying the level of gas-oil contacts (GOC) during drilling

- Preventing the loss of drilling fluid density due to the Gas Cut phenomenon and improving analytical methods during drilling

- Help with Reservoir Compartmentalization

- Petrophysical assessment and identification of reservoirs and reservoir limitations (initial fluid identification and reservoir quality assessment)

- Estimation of reservoir fluid mobility

- Determining the type of hydrocarbons extracted from the reservoir

- Determining production areas in the study area

- Matching the stratigraphy of the formations and the geological connection with other wells

- Estimating the maturity of hydrocarbons in terms of separation, biodegradation and water washing

- Conducting production fluid correlation studies in an area based on field and regional perspective

- Improved interpretation of continuous reservoirs

Benefits

- Separation, extraction and transfer of reservoir fluid compounds in drilling mud that are liquid in atmospheric conditions.

- Evaluation of the advanced analysis technique of mud gas system in the initial stages of exploration and exploitation operations will not cost much.

- It is possible to obtain information related to hydrocarbon compounds for a reservoir and in a specific part of the studied basin by spending less time and money.

- With this method, he predicted the geochemical characteristics of the subsurface reservoirs with acceptable accuracy during drilling and exploration operations in a part of the studied basin, and also prevented any possible risks during drilling.